Unlike conventional microbubble generation technologies, the MicroGas™ technology is not based on the gas dissolution principle but on direct microbubble induction. This results in energy efficient systems that require fewer components to function.

As a consequence, MicroGas™-powered plants are easy to install, operate and maintain and have the smallest possible footprint. MicroGas™ is the simplest and most energy efficient microbubble generator available on the market for flotation and gas transfer (O₃, O₂, CO₂) applications.

Key Benefits

Simplicity

MicroGas™-powered plants require minimal equipment and are therefore easy to install, operate and maintain.

Energy Efficiency

Direct Microbubble Technology means that no pressure is necessary to dissolve gas into the liquid, making MicroGas™ the most energy efficient in the market.

Compact

Flotation, oxygenation and ozonation plants powered by MicroGas™ have smaller footprints and tank volumes.

Products

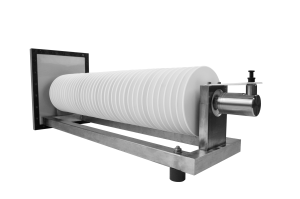

Series S

- Gas flow rates: 1 – 20 Nl/min per unit

- Slide-in installation: the unit is inserted into the tank through a side opening and is then flanched on the tank surface, so that the rotating motor is accessible at any time.

- Automatic cleaning – No downtimes

- Adjustable gas flow rate – Quick & simple

- Withstands extreme temperatures and pH

Series XL

- Gas flow rates: 10 – 75 Nl/min per unit

- Drop-in installation: the unit is dropped into the tank from above. Ideal for retrofitting sedimentation tanks/basin and obsolete DAF plants

- Automatic cleaning – No downtimes

- Adjustable gas flow rate – Quick & simple

- Withstands extreme temperatures and pH

Applications

Flotation

MicroGas™ generates white water for optimal removal of FOG and TS without the need to dissolving the gas into the water, reducing the energy consumption and the footprint of the flotation process.

Gas Transfer

MicroGas™ allows extremely gas transfer efficiency due to the small bubble size produced. MicroGas™-powered reactors can be designed for the transfer of Oxygen, Ozone, and Carbon dioxide.