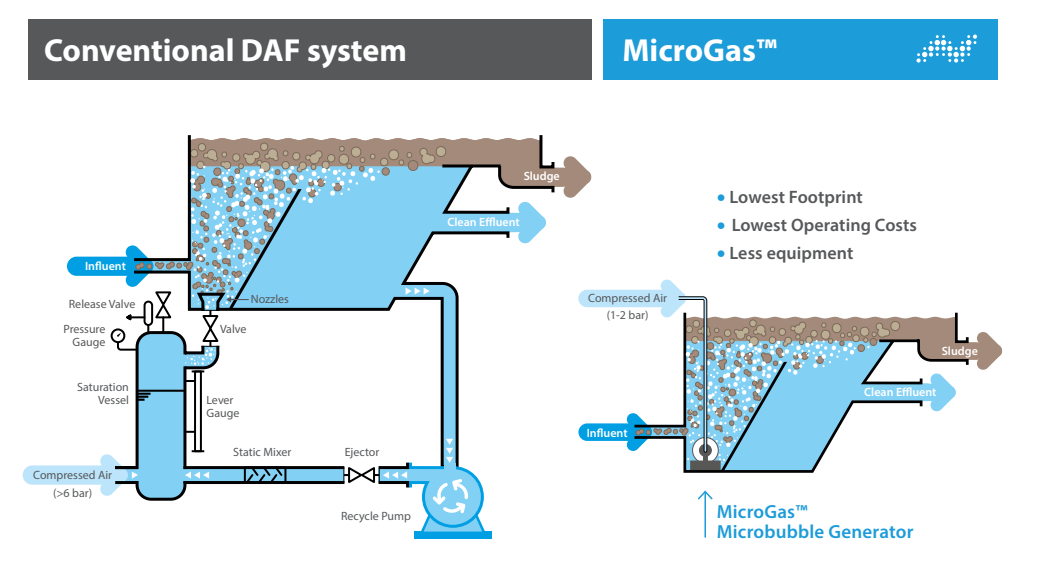

MicroGas™ generates white water for optimal removal of FOG and TSS without dissolving gas into water and hence no recycle stream is required. For this reason, MicroGas™-powered flotation plants can be designed with smaller tank volumes and footprints whilst keeping the required HRT (Hydraulic Retention Time) for an optimal performance. Additionally, our technology uses a fraction of the energy of conventional microbubble generating processes.

Key Benefits

Simplicity

- No recycle stream – minimal equipment required

- Avoid downtimes related to pump and nozzle failures

Energy Efficiency

- Lowest energy consumption < 0,05 kWh/m3

- Up to 90% lower due to lower operating pressures (1-2 bar) independently from salinity and temperature.

Compact

- Lowest footprint

- Adjustable gas flow rate – only changing inlet pressure