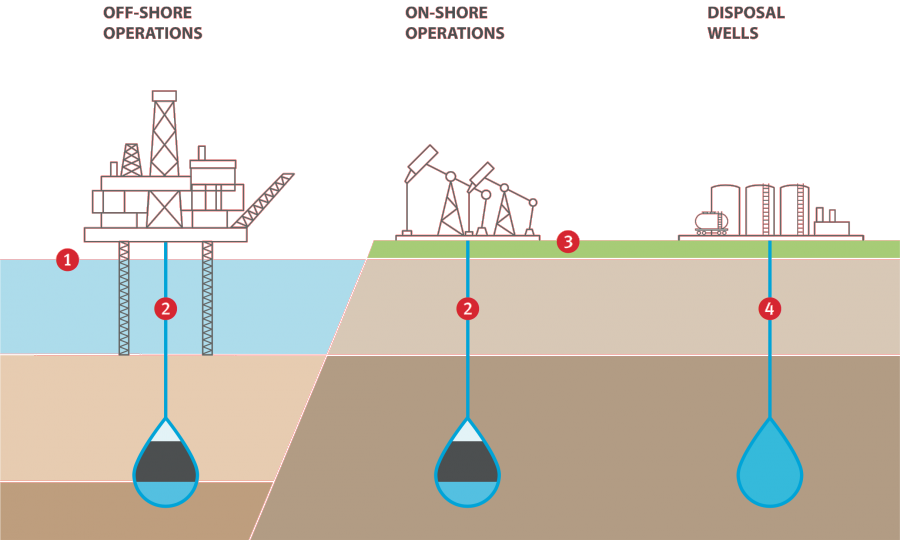

1. OFF-SHORE DISCHARGE

Problem: Non-compliance with ever stricter discharge limits due to high oil content.

Solution: An akvoFloat™ system can cost-effectively replace secondary and tertiary/polishing treatment or upgrade the existing treatment train.

2. OFF-SHORE & ON-SHORE REINJECTION (PWRI)

Problem: Insufficient removal of TSS/clay, bacteria and oil to meet water quality requirements for reinjection.

Solution: The effluent of an akvoFloat™ system can meet any reinjection water quality requirements, replacing conventional secondary and tertiary treatment technologies or upgrading the existing treatment train.

3. ON-SHORE REUSE

Problem: High oil and TSS concentrations make advanced treatment for reuse (e.g. RO) impossible.

Solution: An akvoFloat™ system is the ideal pretreatment for any advanced treatment required for any (beneficial) reuse application.

4. ON-SHORE DISPOSAL

Problem: Insufficient removal of TSS/clay, bacteria and oil to meet water quality for disposal/deep-well injection.

Solution: An akvoFloat™ system can cost-effectively replace secondary and tertiary/polishing treatment or upgrade the existing treatment train.