Due to their small size (40-60 micron) the bubbles produced by MicroGas™ have 600x more surface area than those of conventional diffusers. The larger gas-liquid interface combined with the slow rising velocity of the microbubbles enables MicroGas™-powered reactors to achieve much higher gas transfer efficiencies than competing technologies. Our Direct MicroBubble Technology is extremely energy efficient, since it operates at low pressures and requires lower gas volumes. These features render the use of microbubbles for gas transfer applications economically feasible for the first time – unlike conventional micro and nanobubble generation technologies. MicroGas™powered reactors can be designed with minimal footprints and depths for an effective mass transfer of gases.

Oxygentation – O₂

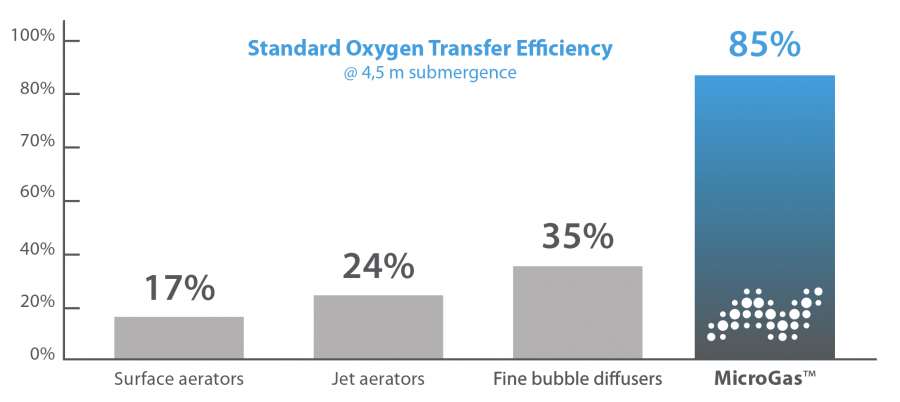

MicroGas™ allows to operate plants at a 50% higher SOTE and to save up to 50% on their energy bills (SAE) than competing technologies.

- SOTE (Standard Oxygen Transfer Efficiency) up to 85%

- SAE (Standard Aeration Efficiency) up to 10 kg O₂/kWh

Ozonation – O₃

Ozone is supplied directly to the MicroGas™ device without the need of additional equipment or booster pumps.Unlike conventional technologies MicroGas™ delivers ozone in form of microbubbles (vs 2-3 mm of conventional technologies) and provides automatic mixing by the rotation of the shaft. This means that the target ozone demand can be achieved faster (lower contact time) and more efficiently, thereby reducing the risk of having to destroy residual ozone.

Key Benefits

- Reduced required reactor height

- Simplification of installation and lower footprint:no booster pump and less piping required

- No chemical cleanings required

Retrofit existing reactors

- Increased treatment capacity of existing reactor

- Fast payback times

Carbon Dioxide – CO₂

In carbon dioxide applications MicroGas™ can provide lower operating costs due to the lower gas volumes and pressures required. As a result of the higher transfer efficiency of MicroGas™ the capital expenditures can be reduced, due to a reduction of the reactor footprint and volume.

- Up to 90% reduction of contact time due to higher transfer efficiency

- Up to 50% lower footprint

- Lower gas volumes required

Carbon Capture

- Lower reaction time required

- Only one-step reactor required -lower footprint

- No clogging

pH Adjustment

- No chemicals required

- Lower maintenance costs -CO₂ is less corrosive